Alis C-Series

Automatic Label Inspection Systems are key components for building closed loop quality control structures. The ALIS camera systems check every label passing through the rewinder, detecting printing mistakes at speeds from 0 to 250 m/min. The rewinder is signaled to stop and position the fault. Process information is collected, allowing accurate quality and cost analysis. Statistical information is organized in easy to read, graphical reports.

Operation

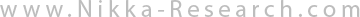

Automatic inspection works by comparing a known good image, called “reference” with the image of each label. The reference image can be taken from the material, from a previous job or from a PDF digital prepress file.

What can be checked ?

The ALIS systems detect typical printing defects like color change, broken or missing print, ink spots and streaks, register change, matrix, splices and missing labels. Optional inspection modules can be added to check variable printing, bar codes and make special measurements.

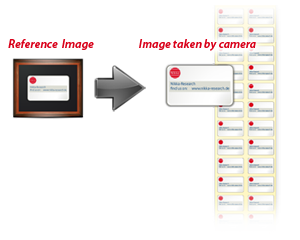

100% inspection on the slitter rewinder

On the rewinder, the automatic inspection system will stop and position each defect for viewing. The operator can visually check the label and repair it by replacement or splicing. On pharmaceutical bi-directional or accumulator rewinders, the repaired label can optionally be re-inspected for 100% security. Inspection on the last process step assures that only quality labels leave the factory. A maximal inspection speed of 250 m/min assures that productivity of rewinder is not reduced. The high resolution, high quality image of the system assists the operator in monitoring the web. Defects are clearly indicated and the operator can quickly identify and repair them. The automatic inspection frees the operator from constantly monitoring the web and reduces eye strain.

Easy to use

No computer knowledge is required to operate a Nikka system. The machines are all equipped with a touch screen, information is displayed graphically and buttons are operated by touching the screen. No mice or keyboards are needed. The machine guides the operator through each procedure. Image on screen exactly matches the image on paper. ALIS systems are available in all major world languages and most operators are comfortable with the system after a few hours of training.

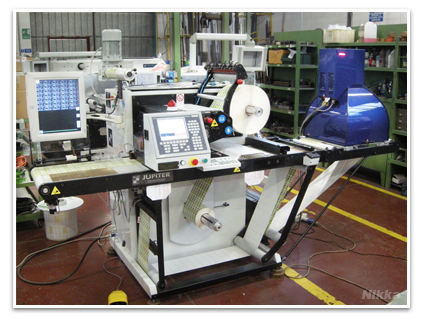

Web widths and options

ALIS C inspection systems are available for two web widths – 330 mm and 420 mm. The C line is available for new rewinders and as retrofit module. The system can be fitted to all popular rewinders. The machine is available with precision CCD black and white and color cameras 2, 4 and 5 Megapixels depending on the application.

Electronic Job Ticket

The electronic job ticket input of the system assists quick job change and configuration. By scanning the bar-code of the factory job ticket, the system retrieves from the MIS server all product data, including prepress PDF and automatically configures all parameters. The operator must command the system to start inspection. Quality managers can set inspection sensitivity in advance together with the job data. With the full job information, the inspection system can additionally prevent a number of finishing mistakes.

Modular, Upgradeable and Reliable

Nikka inspection systems are based on Nikka’s 50 years of experience and innovation in the graphics industry. All machines are modular and field upgradeable for quick repair. One year remote maintenance is included with each C2 system. Upgrade packages will keep your Nikka inspection system competitive for years to come.

English

English

Deutsch

Deutsch