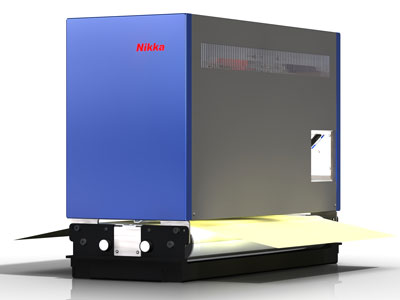

Alis L-Series on Press

Automatic Label Inspection Systems help significantly reduce waste during printing. The ALIS camera systems check every label passing through the printing press, detecting printing mistakes at speeds up to 180 m/min. The operator is alerted of the change and can quickly correct the problem. PDF verification technology is used to automate setup and assure one point of reference. Process information is collected, allowing accurate quality and cost analysis. The printer knows accurately how many good meters are in the ready roll. The risk of reprints is eliminated and the reserve meters can be reduced. Statistical information is collected and organized in easy to read, graphical reports.

Operation on a Printing Machine

Automatic inspection works by comparing a known good image, called “reference” with the image of each label. The reference image can be taken from the material, from a previous job or from a digital prepress PDF file. During inspection, the camera system compares the reference image with the print, allowing for process deviations like colour change, register and die-cutter moves. When the deviation exceeds a set tolerance, ALIS signals the operator, showing the position of the defect and the possible cause.

What can be checked ?

The ALIS system detects typical printing defects like color change, broken or missing print, ink spots and streaks, register change, matrix, splices, missing labels. Optional inspection modules can be added to check variable printing, bar codes, security features and make special measurements.

Materials and Processes

The automatic illumination of the ALIS-L inspection system adapts to practically all types of substrates and processes. Special finishing like hot and cold foil, embossing, metalized substrates and transparent films can be reliably inspected.

Electronic Job Ticket

The electronic job ticket input of the system assists quick job change and configuration. By scanning the bar-code of the factory job ticket, the system retrieves from the server all product data, including prepress PDF and automatically configures all parameters. The operator must only signal the system when the desired print quality is achieved. Quality managers can set inspection sensitivity in advance together with the job data. With the full job information, the inspection system can accurately display printed “good meters”.

A reliable Assisstant

The high resolution, high quality image of the system assists the operator in monitoring the printing process. On the optional second monitor several enlarged views of the web can be displayed at different magnifications. This is a great tool for simultaneous monitoring of color register at both edges of the web, overprint areas and die-cut register. The advanced defect trend and press analysis module assists the operator in the early identification of printing problems. The optional “traffic light” style indicator will alert the operator even if he is not in front of the inspection system. After completion of the job, an itemized report with all important statistics gathered during the print is saved in PDF format.

Easy to use

No computer knowledge is required from the operators of Nikka systems. The machines are all equipped with a touch screen, information is displayed graphically and buttons are operated by touching the screen. The machine guides the operator through each procedure. Image on screen exactly matches the image on paper. ALIS systems are available in all major world languages and most operators are comfortable with the system after e few hours of training. No mice or keyboards need to be mounted on the printing machine.

Web widths and options

ALIS L systems are available for three web widths – 330 mm, 420 mm, 560 mm, 620 mm and 760 mm. The L2 model with its compact form fits on most printing presses and is available for both new presses and as retrofit. The Alis L2 is highly customizable with Barcode, Variable Data and OCR optional modules. The machine is available with precision CCD color cameras with resolutions 2K, 4K, 6K and 8K depending on the application. Workflow systems (inspect on press, repair on rewinder) are supported with recording defect coordinates in a roll map and controlling process down-stream equipment (turrets, slitter rewinders) to eject the waste sections.

Modular upgradeable and reliable

Nikka inspection systems are based on Nikka’s 50 years of experience and innovation in the graphics industry. All machines are modular and field upgradeable for quick repair. One year remote maintenance and upgrades is included with each L2 or C2 system. Upgrade packages help keep your Nikka inspection system competitive for years to come.

English

English

Deutsch

Deutsch